Quick-Lock Tubing - Compressed Air System ½" TO 2½"

Simply stated – There is no equal

Quick-Lock has taken piping systems to a new level. Without compromising any structural strength, Quick-Lock provides an aluminum product that is ten times lighter than steel. This system is easier to install than plastic and delivers a quality of air, nitrogen, vacuum or inert gas that is equal to that of a high cost stainless steel system.

Superior Quality

Quick-Lock tubing is manufactured from a non-corrosive aluminum that prevents rust and system deterioration while maintaining

a high quality of air delivery suitable for all internal and external applications.

Quick-Lock piping solution offers superior strength within a lightweight design. Heralded for its innovative design,

Quick-Lock offers the performance of heavy, traditional steel piping, at the cost of systems using plastic.

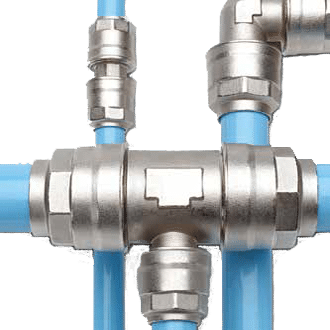

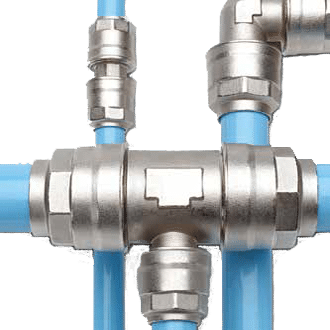

Quick-Lock is secured by nickel-plated

brass fittings that provide the deepest level of engagement. Its revolutionary lock-and-seal design ensures a totally safe, leak-free system for all compressed air, vacuum, nitrogen and inert gas applications.

Total Solution

Quick-Lock offers a total solution for Compressed Air, Vacuum, Nitrogen and Inert Gas applications.

Ranging in size from 14 mm (½”) to 63 mm (2½”) for Quick-Lock and 70 mm (2½”) to 273 mm (10″) for Big-Lock, Four color options to meet all system demands. With the pairing of Quick-Lock and Big-Lock, the system can easily provide piping for any application from a 1–2 bay garage to a large industrial manufacturing facility

Ease of Installation

Quick-Lock offers the easiest and fastest installation available. There is no welding, gluing or threading, and very little skill is needed for a professional installation.

With the purchase of nylon clips or wire hangers, an installation crew can clip tubing securely to a wall or hang from the ceiling and around beams. No special tools are required and both pieces are easily adjustable for a quick and efficient install.

Features & Benefits

- Manufactured from marine-grade aluminum that prevents rust and system deterioration

- Lightest product in the market

- One-tenth the weight of same diameter steel

- High level of structural strength

- Ease of installation compared to competition

- System flexibility allows for simple modifications and/or additions

- High flow rates / low pressure losses

- Smooth internal diameter of tube maintained throughout life of system

- Lowest cost of ownership available

- Enormous level of piping inventory avoids lengthy lead time

- 30 years of combined design and user experience to support customer base

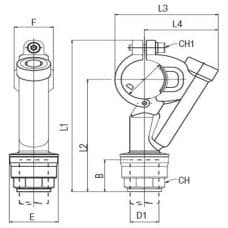

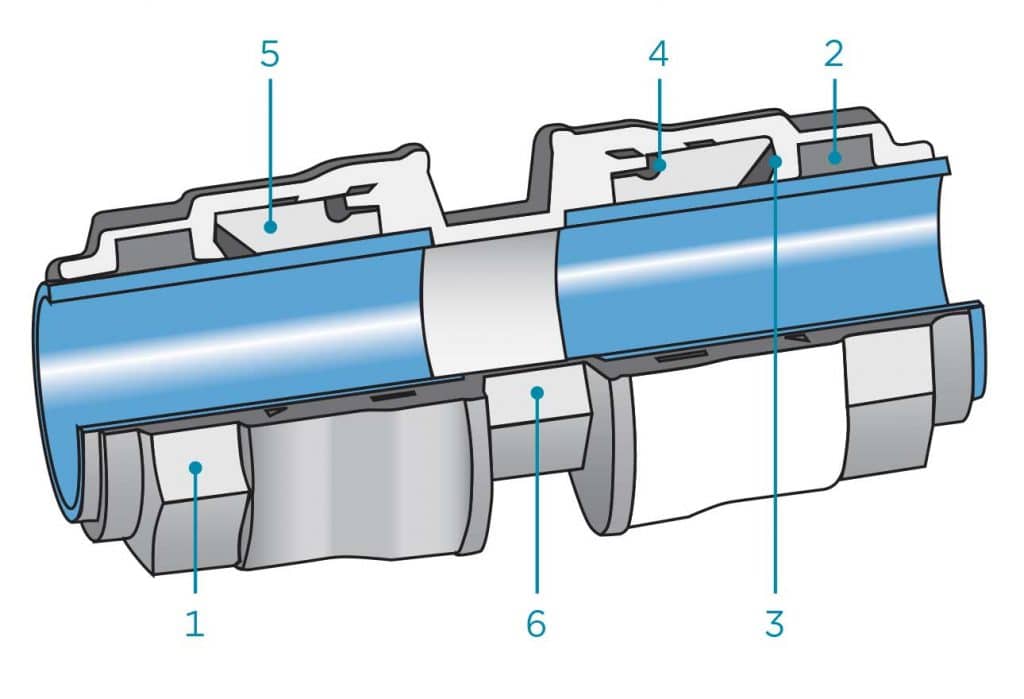

Nut: Nickel-Plated Brass

Seal: High Nitrile

Clamping Washer: Inox AISI 304

O-Ring Seal Made in NBR

Safety Ring: Technopolymeric

Body: Nickel-Plated Brass

PRESSURES

Minimum Pressure -0.99 bar (-29.6 Hg)

Maximum Pressure 15 bar (220 psi)

COMPATIBLE FLUIDS & GASES

Compressed Air

Vacuum

Inert Gases

THREADS

Male threads taper in conformity with ISO 228 Female threads in conformity with ISO 228

TEMPERATURES

Minimum temperature -4° F (-20° C)

Maximum temperature 176° F (+80° C)

FIRE RESISTANCE

The system does not stoke or propagate any fires

Don’t Jeopardize Air Handling Efficiency

Compressed air piping is responsible for the delivery of compressed air to the point of use. Its material, age and condition impact both system reliability and air quality.

Compressed air piping made from iron will rust and corrode, creating buildup on the interior and reducing the functional diameter. This buildup results in pressure drop within the system, contributing to high levels of contamination and poor air quality